CCS 101

What is CCS?

CCS stands for Carbon Capture and Storage. Often used interchangeably with another acronym – CCUS or Carbon Capture, Utilization, and Storage – both refer to the phases of a carbon management system, which includes the capture of CO2, the transport of captured CO2, and either utilization of CO2 for a secondary use (for example, as an additive to food-grade beverages or for enhanced oil recovery (EOR)) or permanent geologic storage (also called sequestration).

Carbon is in everything. Carbon dioxide (CO2) is a molecule of carbon and oxygen – typically in the form of gas – which forms from a variety of processes, including plant and animal decomposition, and from burning some types of carbon, like natural gas, coal, and other fossil fuels. In everyday life, these activities produce CO2, which, when it goes into the atmosphere, can combine with other greenhouse gases (GHGs) and can increase the temperature of the atmosphere because the new mix of gases in the air traps heat from the sun’s radiation better, impacting the temperature on Earth’s surface.

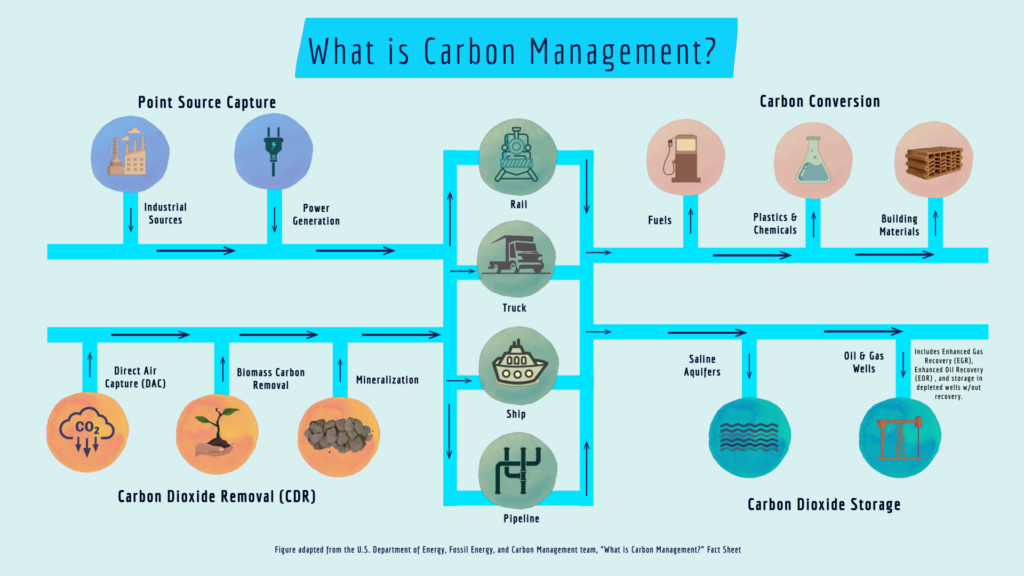

What is carbon management?

Carbon management refers to the many types of infrastructure, processes, and engineering that can be used to help reduce the amount of carbon-dioxide (CO2) emissions released into the atmosphere from certain processes, like when certain types of power facilities generate electricity from coal or natural gas, and then either permanently store the captured CO2 or use it for something else.

What are the 3 phases of a CCS System?

1. Capture

The first phase is capture, during which carbon dioxide (CO2) air emissions produced by industries or power generation facilities are trapped or CO2 is removed directly from the air. Capture can also occur from “ambient” air, which is the air all around us that we breathe every day. Systems that trap and remove CO2 from ambient air are called direct air capture (DAC). DAC technology is very new but offers a way to reduce the amount of CO2 already in the atmosphere and permanently store or sequester it.

2. Transport

Once captured, the CO2 must be transported as the second phase of the system. Transport can happen in a few different ways—by truck, ship, or pipeline. But pipelines are the most common way to transport captured CO2. To prepare for transport, the captured CO2 is compressed through a series of equipment, either into a more efficient gas for transport, or compressed all the way to a liquid state.

3. Storage

The third phase is Storage, refers broadly to a handful of places that captured CO2 can end up. Captured CO2 can be utilized for other purposes, such as low-carbon cement, fuels, or in carbonated beverages at food processing plants. It can also be used for a process called Enhanced Oil Recovery (or CO2-EOR). During CO2-EOR, pressurized CO2 is injected into a wellhead, causing more oil to come up from the field. Many oil and gas companies are interested in using CO2-EOR methods to increase output from oil and gas fields, which make the economics of CO2-EOR attractive for companies looking to capture and sell CO2. Storage refers to permanent, underground geologic storage, where storage represents various options that permanently trap CO2 so it cannot go into the atmosphere. Suitable rock formations are required to safely house the CO2 deep below the Earth’s surface, where the CO2 naturally mineralizes and dissolves over time. CO2 can also be permanently stored in other types of products, such as concrete and cement